When precision, efficiency and material quality are essential, custom cut metal offers a reliable solution for a wide range of industries. From construction and manufacturing to design and DIY, tailored metal cutting services ensure that every component fits perfectly, reducing waste, saving time and enhancing the overall quality of the finished product.

For businesses and individuals across the UK, Forward Metals provides expert custom metal cutting services designed to meet specific requirements with accuracy and speed.

What Is Custom Cut Metal?

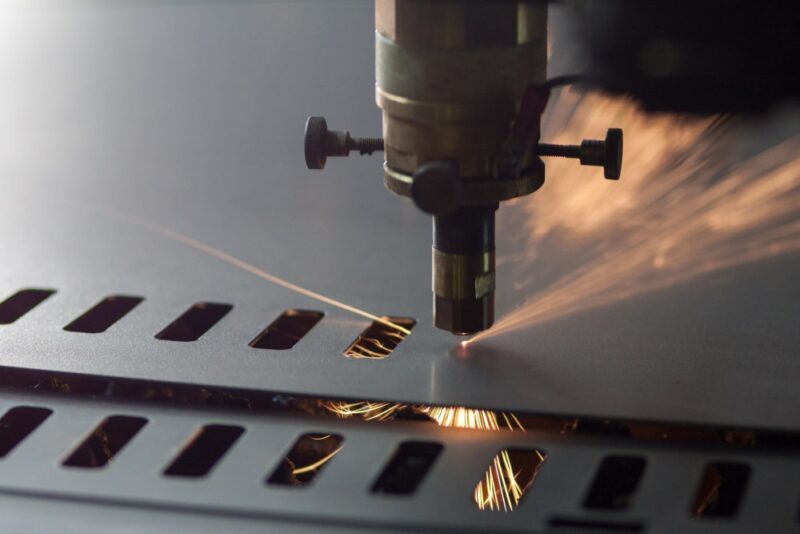

Custom cut metal refers to metal materials that are cut to specific measurements, shapes or designs based on customer requirements. Rather than ordering standard lengths or sizes and cutting them down on-site, customers can receive metal components that are ready to use upon delivery.

This service is particularly valuable for tradespeople, engineers, and fabricators who require consistent accuracy and cannot afford delays caused by on-site modifications. It also benefits hobbyists and small business owners who may not have access to industrial cutting equipment but still need a high-quality finish.

Available Metals and Cutting Options

Different projects require different types of metal, and Forward Metals understands the importance of offering choice. Their custom cut service includes a wide selection of metals, such as aluminium, stainless steel, brass, copper and mild steel. Each material comes in various finishes and thicknesses, allowing customers to choose the right combination for their specific application.

Whether you need polished stainless steel for a decorative installation or strong mild steel for structural work, Forward Metals can cut sheets, bars, plates and more to your required size. The result is a bespoke solution tailored to your needs, with no unnecessary material left over.

Saving Time and Reducing Waste

One of the most compelling reasons to opt for custom cut metal is the efficiency it brings to a project. By removing the need for cutting on-site, customers benefit from a cleaner workspace, reduced risk of error and less wasted material. This not only improves productivity but also reduces overall costs.

For commercial projects where timelines and budgets are closely monitored, having ready-to-fit metal components delivered directly to site can make a significant difference.

Trusted Service from Forward Metals

Custom cut metals has built a strong reputation for its commitment to quality and customer satisfaction. Their custom cutting service is backed by years of industry experience and supported by a knowledgeable team who understand the importance of precision.

With nationwide delivery available, customers can rely on prompt turnaround times and a straightforward ordering process. Whether you need a one-off piece or a large batch of components, Forward Metals provides a flexible and professional service that ensures you receive exactly what you need.

Why Pre-Cut Metals Lead to Faster Assembly

Time-sensitive jobs require flawless execution. Pre-cut metals reduce handling steps, eliminate cutting errors and streamline workflow.

Key Benefits:

- No delays from broken saw blades or inaccurate cuts

- Better fitting parts improve overall build speed

- Clean cuts reduce prep time before welding or fastening

- Easier inventory management with labeled and sorted pieces

In high-volume work, even minutes saved per unit can mean hours gained over time. Pre-cut components turn chaos into flow.

Best Practices for Ordering Custom Cut Metal

To get the most out of custom cutting, a few planning steps can protect your budget and help ensure better results.

Consider the following tips:

- Double-check all measurements before sending specifications

- Choose metal grade based on strength, corrosion resistance and finish

- Include diagrams if the design includes cut-outs, holes or unusual edges

- Request deburring or edge finishing if needed for safety or appearance

Every project has unique demands. Providing clear details from the start avoids delays and helps achieve cleaner results.

Custom Cut vs. In-House Cutting

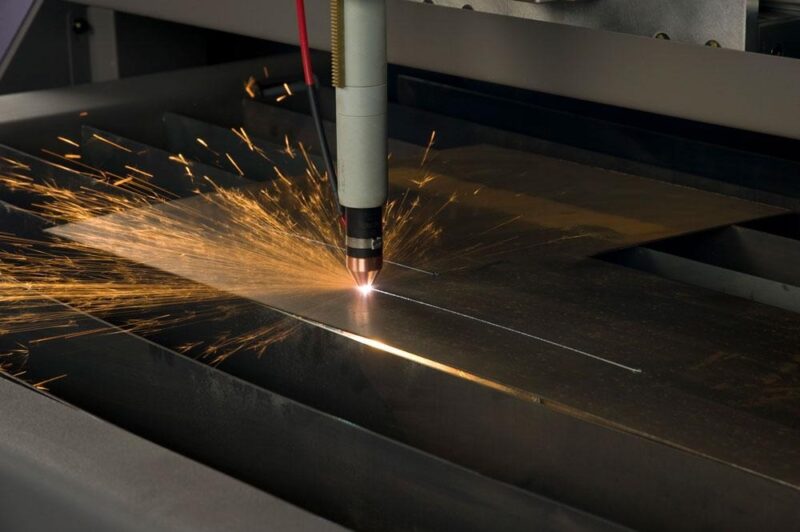

Some businesses still use in-house tools to trim stock metal. While that works in low-volume scenarios, it often leads to complications.

Manual cutting introduces inconsistencies. Angles vary, cuts drift, and even slight size differences cause headaches during assembly. Tool wear and maintenance also drain time and resources.

Custom cutting, by contrast, guarantees consistency. Machines follow precise instructions, reducing defects and rework. By outsourcing cuts, teams can focus on core work and avoid setup delays.

Conclusion

Custom cut metal improves project outcomes in nearly every sector. It reduces waste, saves time and enhances the fit, finish and function of every component. Businesses benefit from better workflow and lower costs. Hobbyists and professionals alike enjoy precision without the need for heavy tools.

Forward Metals stands out for its expertise, range and reliability. Their custom cutting service makes complex projects easier and faster to complete. With consistent quality and fast delivery, they remain a trusted partner for any metal job—big or small.