Factory applied coatings are an essential part of modern building material manufacturing, delivering superior performance, durability, and finish consistency compared to onsite painting. These solutions are engineered for efficiency, aesthetic quality, and long term protection against weathering, corrosion, and wear. For architects, builders, and fabricators working with metal, timber, or composite materials, choosing the right coating partner ensures that pre finished products arrive ready for installation and perform as expected over the life of the structure.

Why factory applied coatings outperform onsite finishes

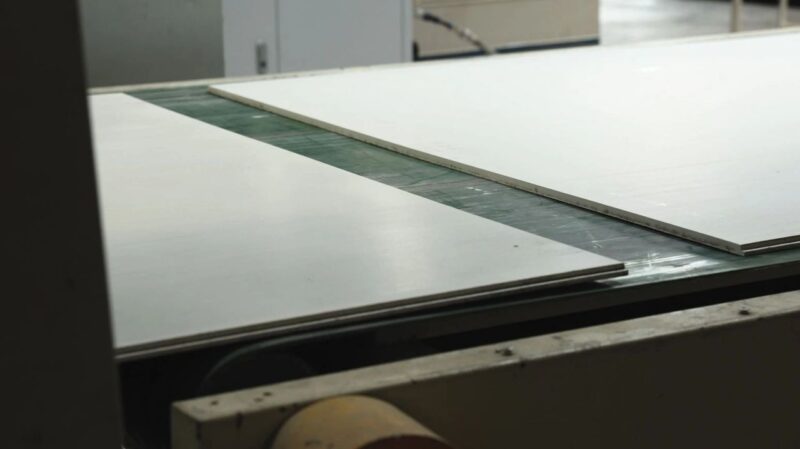

Factory applied coatings are applied under controlled conditions, which directly impacts quality and consistency. In a factory environment, temperature, humidity, application method, and curing time are all tightly regulated, resulting in a finish that is uniform, well bonded, and free from common onsite painting issues such as runs, sags, or contamination.

Materials like aluminium cladding, steel framing, architectural panels, and engineered wood benefit from coatings that adhere consistently and develop full mechanical and chemical properties before leaving the line. The result is a finish that resists UV degradation, moisture infiltration, and surface abrasion far better than coatings applied after installation.

QC Architectural specialises in factory applied coating systems that meet both aesthetic and performance requirements for building materials. Their processes ensure that every product is coated to specification, inspected for quality, and protected against handling damage during transport and installation.

Factory finishes also reduce project risk and schedule pressure. Onsite painting often depends on weather windows, skilled labour availability, and site access—all variables that can delay completion. By contrast, factory finishing streamlines delivery and reduces the need for touchups or warranty work later.

Common coating types and performance features

The type of coating chosen depends on the substrate and the intended use of the material. For metal building components, high performance powder coatings and liquid architectural finishes offer excellent adhesion, colour retention, and corrosion resistance. Powder coating in particular creates a tough, uniform layer that is environmentally friendly and efficient to apply.

For timber and engineered wood products, UV cured lacquers, stains, and sealing systems are designed to enhance grain appearance while providing moisture resistance and dimensional stability. These coatings penetrate and protect the wood without obscuring its natural texture, which is critical in architectural applications where aesthetics matter.

Composite materials often require specialised primers and topcoats that bond well to substrates like fibre cement or poly bonded layers. Selecting coatings that expand and contract with thermal movement helps prevent cracking or delamination over time.

QC Architectural works with clients to specify coatings that align with both performance expectations and regulatory requirements, whether for fire resistance, colour matching, or environmental compliance.

Benefits in construction workflows and lifecycle outcomes

Pre finished building materials arrive at site ready for installation, eliminating the need for last minute painting and reducing site waste. This not only improves labour productivity but also enhances safety by reducing the need for elevated work or spray equipment at height.

Factory applied coatings also support better lifecycle outcomes. Materials coated under controlled conditions tend to have longer service lives and lower maintenance costs. This contributes to reduced whole of life costs for building owners and stronger performance in warranty evaluations.

Quality control systems play a major role in these outcomes. QC Architectural integrates inspection points throughout the coating process, including thickness measurements, adhesion testing, and final visual checks to ensure conformity to specifications before release.

Conclusion

Factory applied coating solutions elevate building materials from functional components to high performance architectural elements. By applying coatings in controlled environments with tested processes, manufacturers achieve superior finish quality, durability, and performance that onsite painting simply cannot match. Whether working with metal, timber, or composites, partnering with a specialist like QC Architectural ensures that pre finished materials meet both aesthetic intent and long term performance expectations. From improved installation workflows to enhanced lifecycle value, factory applied coatings deliver tangible benefits for modern construction projects.